Product details

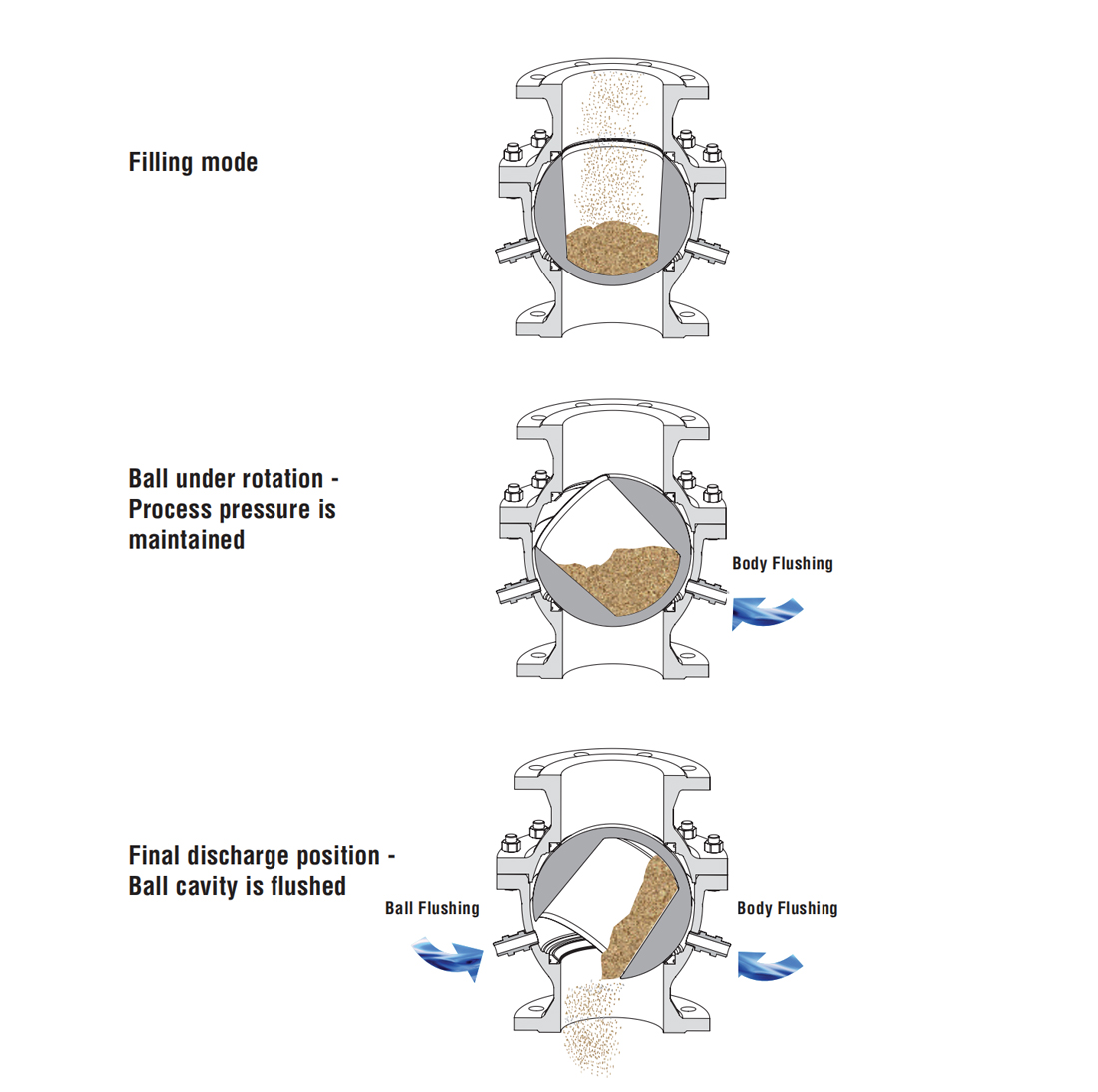

Main features:The deslagging ball valve is designed to solve the problem of safely removing particles or debris from the separation medium during the process in the pulp and paper industry. Based on the many years of experience of Laiside Valve Co., Ltd. in producing hard-sealed ball valves and wear-resistant ball valves, it is specially designed to remove particles or debris from the medium while maintaining the process pressure to ensure the normal operation of the process and the continuous production output of the enterprise.

Product Features:

Temperature range: ≤450℃

Diameter size: NPS2-8”(DN50-200)

Pressure level: PN16-PN100; ASME 150LB-ASME 600LB

Flange connection: Chemical Industry Department; ASME B16.5

Flange connection surface: RF; FM

Body design: Forged, cast two-piece

Ball design: Ball sealing surface covered with alloy

Seat design: Seat sealing surface covered with alloy

Reliable valve design improves process uptime. The design discharges solids while maintaining full process pressure and minimizes the loss of process media.

The dustproof structure of the valve seat prevents the valve seat from being unable to open and close due to the accumulation of gas behind the valve seat.

Since the metal seat is covered with an alloy layer, leakage is minimized.

Two flushing ports are connected to effectively flush the valve body and ball cavity during pressure opening and closing.